- Allergies and Air Pollution's Effect on Health

- Asthma & How it is affected by Air Pollution

- Air Pollution & Cancer

- Air Pollution's Harmful Effects on the Elderly

- More about HEPA and Carbon activated Filters

- Different types of air filters

- Mold Spores and Indoor Air Quality

- UV Air Purifier Guide

- What causes bad indoor air quality?

- How do Air Purifiers Work?

- Air Pollution May Cause Respiratory Infections

- Air Pollution in the workplace

- Pet Dander's Effect on Air Quality and Asthma

- Air Pollution & Sleep Apnea

- Top 5 Reasons Why you should purify Air

- What you need to know about indoor air

- How Pets cause allergies

- Tips on Choosing the Right Air Purifier

- Multiple Chemical Sensitivity

- What are Dust Mites?

- The History of Air Purifiers

- Air Pollution Problems of the new home

- 5 Ways to Reduce Your Pollen Allergies

- Sinusitis Causes and treatments

- What is HEPA filtration?

- Air purifiers and Wood Smoke

- Home Air purifiers and Cigarette Smoke

- Volatile Organic Compounds (VOCs)

- Formaldehyde Air Pollution

- Is your air purifier ozone free?

Reverse Osmosis Technical Center

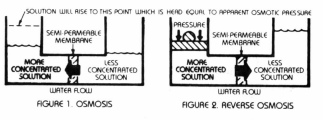

What Is Reverse Osmosis

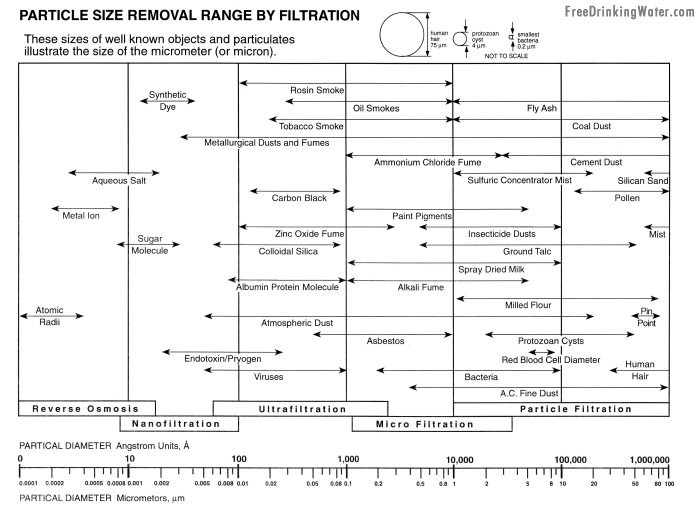

Reverse Osmosis, also known as Hyper-filtration by the industry, represents state-of-the-art in water treatment technology. Reverse Osmosis (RO) was developed in the late 1950's under U.S. Government funding, as a method of desalinating sea water. Today, reverse osmosis has earned its name as the most convenient and thorough method to filter water. It is used by most water bottling plants, and by many industries that require ultra-refined water in manufacturing. Now this advanced technology is available to homes and offices for drinking water filtration.

How It Works

In short, it is the process by which water molecules are forced through a 0.0001 micron semi-permeable membrane by water pressure. Long sheets of the membrane are ingeniously sandwiched together and rolled up around a hollow central tube in a spiral fashion. This rolled-up configuration is commonly referred to as a spiral wound membrane or module. They are available in different sizes for processing different quantities of water. Typically, a module for home water treatment is as small as 2" diameter and 10" long, while one for industrial use may be 4" diameter and 40" long.

For the membrane to be usable it must be in some type of container (membrane housing) so pressure can be maintained on its surface. It is this pressure that supplies the energy to force the water through the membrane, separating it from unwanted substances. The most amazing aspect of RO is that the substances left behind are automatically diverted to a waste drain so they don't build up in the system as with conventional filtering devices. This is accomplished by using a part of the unprocessed water (feed water) to carry away the rejected substances to the drain, thus keeping the membrane clean. This is the reason to why RO membranes can last so long and perform like new with minimum maintenance even after years of operation.

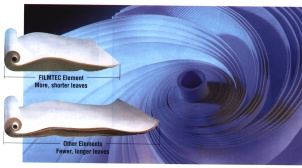

Higher Performance RO Membranes Begin With Shorter Leaves

The heart of a reverse osmosis system is, of course, its membrane. Yet not all membranes are made the same. Different manufacturers fabricate their membranes differently. For example, spiral-wound membranes are comprised of membrane "leaves" —individual sheets of membrane through which feed water passes and is filtered. Some membrane brands have fewer and larger leaves. Some have more and shorter leaves. Short-leaf design costs more to fabricate, but is advantageous because less pressure is required to deliver water to the end of each leaf, and more uniform flux is maintained from one end of the leaf to the other. The result is a highly efficient membrane —one that provides safer drinking water and a longer life. For example, APEC's high quality water is achieved by advanced reverse osmosis membranes which have up to twice as many leaves and each leaf is 1/3 to 2/3 shorter than those in other membranes. Besides the overall system design and the quality of parts used, the membrane is the reason why different ROs have different rejection capabilities.

Flow Rate Of Reverse Osmosis Systems

All reverse osmosis systems are rated (and priced) by their flow rates (Gallons of Product Water Produces Per Day). The effectiveness and productivity of RO systems increase with greater water pressure and temperature. The actual flow rate (in GPD) of any reverse osmosis system depends on your home water pressure and temperature. This is why all of our systems are named as they are, for example: 36/45 GPD means it is rated at 36 GPD at 50 psi of water pressure, 45 GPD at 60 psi. While the industry standard* is set at 60 psi, we know that not everyone's cold water is at 60 psi and 77 degrees F. Instead of misleading customers into thinking that a 45 GPD system will guarantee a flow rate of 45 GPD, we remind you that you might get less than 45 GPD —perhaps 36 GPD or even less if your pressure and temperature are very low! So when flow rate is critical for you, you need to consider all these factors.

*Please note that the industry standard is not necessarily followed by all vendors. We have seen other RO systems claiming 100 GPD at 100 psi —very unrealistic input water pressure! So do check on these facts before you make a buying decision.

| Amount of water produced in 1 hour (at 50 psi & 77ºF) |

|

| *Tested in open atmospheric tanks at 50 psi input water pressure and 77ºF input water temperature. |